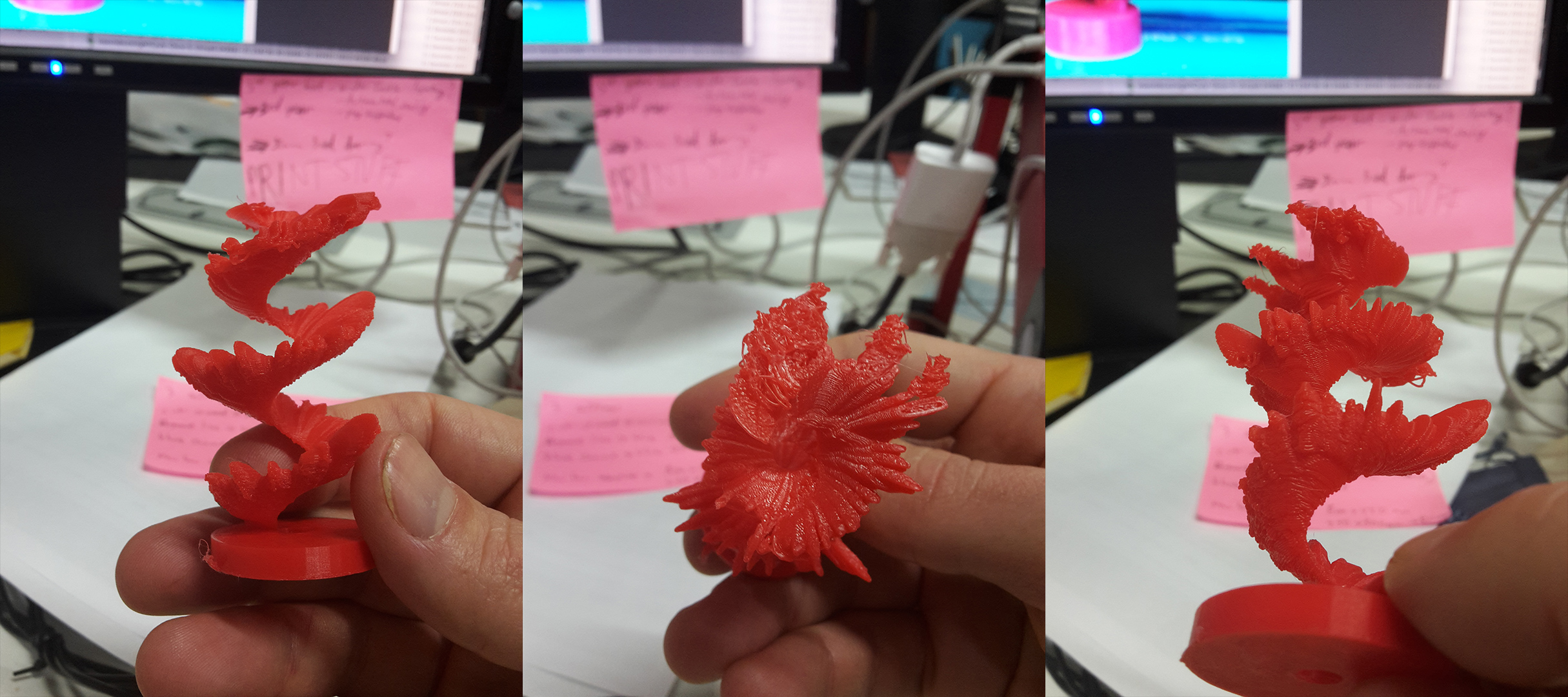

Oops.

Too skinny – about 30mm wide in the base, 65mm tall. shakes too much during the build.

It could also be that it’s not sticking to the base plate properly – this happened with the next print:

![]()

I found that you can change the generated gcode to turn the base temperature down. I changed it to 40C, because it waits to build until the temp is within 3C of the target temperature, and it took ages to cool down to 40C even in a cool office. the results are better, but there’s still maybe 1mm of warp under that back left side.

The upside is that I’ve got a nice gallery of failures after running all these tests!

![]()